Overview

Tong has a continuous commitment to provide the most efficient and technically advanced vegetable sizing equipment to growers and packers worldwide. We are proud to offer unrivalled experience, alongside the latest advanced solutions, ensuring the complete solution to your vegetable and onion sizing needs.

ADVANCED, RELIABLE VEGETABLE SIZING LINES

Tong’s potato and vegetable sizing lines are custom designed to achieve all your vegetable sizing requirements. Built to guarantee gentle handling, minimal maintenance, optimum safety and ease of use, you can rest assured both buildings and labor will be utilized in the most efficient way when you chose Tong.

Whether you are sizing potatoes, onions, carrots, parsnips, brussels sprouts or bulbs, you can be sure that when you choose a Tong vegetable sizing line, you are choosing the most advanced vegetable handling equipment. Designed to offer reliability and profitability for many years to come.

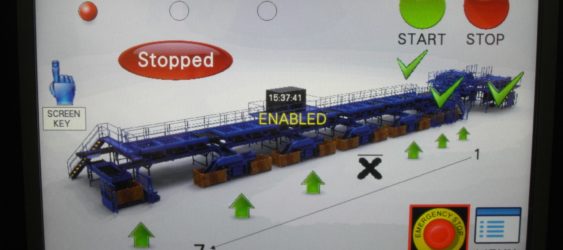

Featuring integrated blue inverter technology and total Pro-Series HMI touch-screen control, Tong’s advanced control systems give you complete control of your vegetable sizing equipment, for maximum productivity and minimal downtime.

Features

Blue Inverter Technology

All Tong vegetable sizing lines are built with Tong’s Blue Inverter Technology, offering the very best energy efficiency. All complete with electric Inverter Variable Speed Direct Drive, significantly increasing energy savings and reduced running costs.

Built-in Power Efficiency

Tong’s latest vegetable sizing equipment is designed to operate with optimum power efficiency. Incorporating energy efficient power-saving modes, which identify and shut-off any equipment that is not in use. This new feature does wonders for your green credentials whilst reducing energy costs too!

Auto-Touch HMI Control

Tong offers advanced and intelligent Auto-Touch HMI Pro-Series controls as an option on all its latest sizing equipment. Bringing a level of control and system intelligence to the vegetable handling industry – one that would more commonly be seen in the aviation and rail industries. Tong’s touch screen controls truly are the most advanced on the market, offering control capabilities that will leave you feeling quite literally empowered at the touch of a button!

The latest intelligent Pro-Series features, are built on next generation hardware and programming alowing very obvious efficiencies. As such, Tong’s state-of-the-art controls include a series of modules including a diagnostics module, an enhanced safety module and a maintenance schedule module to provide advanced system monitoring and reporting.

Pro-Series E-Stop Finder

Tong’s latest Pro-Series controls include an intelligent emergency-stop finder which visually identifies on the touch-screen, the precise location of any emergency-stop which is activated. This new feature saves time and minimises downtime.

Pro-Series User ID

The new Pro-Series controls feature an advanced user module, allowing operators of all levels to access and control equipment, based on their level of training. This means users at standard levels are able to see visually, the machine’s status or diagnostics. In many cases allowing them to rectify and reset any alerts without the need for an engineer.

Pro-Series Diagnostics

The intelligent Diagnostics module provides users with continuous status monitoring so that it the event of an issue, the exact location is automatically pin-pointed, enabling quick and easy problem solving and resetting. Any such issues are shown visually on the touch-screen, allowing users of any level to see exactly where the problem has occurred. This feature significantly reduces downtime. removing the guess-work on machine trips and fault-finding.

Pro-Series Maintenance

The new Maintenance Schedule module allows the run-time of any machine component to be recorded in terms of running hours or calendar periods, indicating when any part may need to be maintained or changed. This makes any scheduled maintenance much more efficient. This new feature not only improves the efficiency of maintenance, but it also allows users to be more pro-active in their maintenance routines. Minimising wear and repair costs and saving time.

Pro-Series Safety

The Enhanced Safety module means that when any essential maintenance is required, the designated area can be isolated in a ‘safety-stopped’ condition, so that maintenance can be carried out safely, whilst other parts of the machine can continue to run in a normal operational status. Again, keeping any downtime to an absolute minimum.

Box-Fill Beacons

The latest Tong sizing lines can be manufactured to incorporate illuminated box filling beacons when several box fillers are in use. Making it much quicker and easier for forklift drivers to see which boxes need to be changed next. This new feature saves time, whilst improving the efficiency and throughput of Tong sizing lines.

Gentle Handling

At Tong we understand that gentle handling is your priority and that’s good enough reason to make it ours too! All Tong equipment is designed with the gentlest handling in mind. From fine-tuning the speed and agitation of sizing screens to suit different crop varieties, to designing a sizing line that ensures crop is transferred smoothly and gently from one process to the next. You can be sure that a Tong sizing line offers the gentlest possible handling with minimal impact, for maximum returns on your crop.

Heavy Duty Construction

With heavy duty design and build quality, Tong equipment really is built to last. Manufactured with precision laser-cut steel, first class fabrication, and world-renowned specialist exterior paint on all mild steel equipment. You can be sure that Tong handling equipment will stand up to demands for years to come.

Gallery

Specifications

INTELLIGENT

HMI ControlTong offers advanced and intelligent Auto-Touch HMI controls that will leave you feeling quite literally empowered at the touch of a button!

CUSTOM BUILT

0.6 to 2.4m wideAvailable in a range of standard widths, Tong sizing lines can be designed to meet your exact sizing needs, however big or small.

HIGH OUTPUT

Up to 35 tonsBuilt to keep up with your sizing demands, Tong’s sizing lines are designed to efficiently and gently size up to 35 tons of crop per hour.

Share this post