Overview

Tong even flow hoppers, also known as rise and fall hoppers, are the ideal crop infeed solution to ensure a continuous and controlled feed of crop onto any vegetable handling line, whether you are grading potatoes, washing carrots or packing onions!

Manufactured in mild or stainless steel specification, Tong even flow hoppers are suitable for handling washed or unwashed crop and can be specified to meet the highest food safety requirements when operating within a high-care vegetable processing application.

advanced rise and fall Hoppers

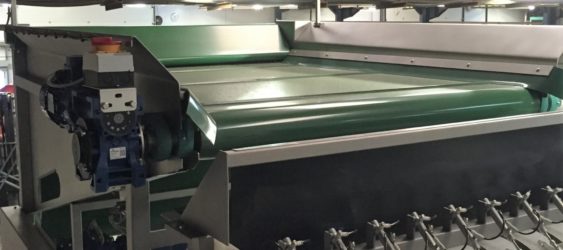

The even flow hopper’s conveyor lowers at the feed-on end to form a holding hopper for crop. Featuring a microprocessor controlled sensor to control the level of the crop within the hopper at any time, when the conveyor in the even flow hopper re-starts the feed of crop, it rises to gently and evenly feed crop out of the hopper for onward processing. Popularly used to receive crop from a box or bag tipper, or to accumulate crop prior to ensuring a steady feed of crop onto an optical sorting unit, sponge dryer, packing machine or grading unit, the even flow hopper is versatile in it’s use across a wide variety of vegetables and in many crop infeed situations.

No matter what size or capacity even flow hopper you require, you can be sure of a robust, reliable and gentle hopper from Tong. Contact our experienced Tong Engineering hopper team today to discuss your requirements.

Features

BLUE INVERTER TECHNOLOGY

All Tong hoppers feature Tong’s Blue Inverter Technology inverter direct drive motors which run on 87 Hz variable speed, offering over 50% less power consumption.

HEAVY DUTY CONSTRUCTION

Tong hoppers are built upon a heavy duty steel gauge design, consisting of chain and lathe construction. Featuring heavy duty 4” pitch chains as standard, with dual driven drive shaft, Tong hoppers offer a total maximum strain of 64 ton. What’s more, hoppers wider than 1800mm are constructed with a central runner fitted to the hopper chassis, offering additional, robust support to the hopper lathes.

WORLD-CLASS COMPONENTS

Tong sources its equipment components from some of the world’s best renowned suppliers for quality, reliability and innovation. Including motors from SEW, Lenze and Motovario, rollers and drum motors from Interroll, bearings from RHP and SKF, and electrics from Eaton Moeller and Omron.

Share this post